MM Kembla has combined the experience and knowledge of over 100 years of Australian metal tube manufacturing with German engineering to produce the KemPress Stainless press-fit connection system.

With a warranty of 25 years for potable water and fuel gas applications, and a design life of 50 years, KemPress Stainless offers you the peace of mind and the simplicity you want with the highest quality, most reliable and trusted press-fit system.

KemPress Stainless Steel Fittings – Australian Standard AS 3688

MM Kembla® has combined the experience and knowledge of over 100 years of Australian copper tube manufacturing with press-fit technology & engineering to produce the KemPress® copper press-fit connection system. With a warranty of 25 years, and a design life of over 50 years, KemPress® offers you peace of mind and the simplicity that you want.

MM Kembla® has combined the experience and knowledge of over 100 years of Australian copper tube manufacturing with press-fit technology & engineering to produce the KemPress® copper press-fit connection system. With a warranty of 25 years, and a design life of over 50 years, KemPress® offers you peace of mind and the simplicity that you want.

Kembla Stainless Steel Tube and KemPress Stainless press fittings have been optimised for combined use, with fittings produced using Kembla Stainless Steel Tube. When you need the highest quality stainless streel press-fit system, use Kembla Stainless Steel Tube, KemPress Stainless Fittings and KemPress Press Tools. Our press tools with jaws to suit stainless steel are of the highest quality, are the lightest on the market and have the longest intervals between servicing.

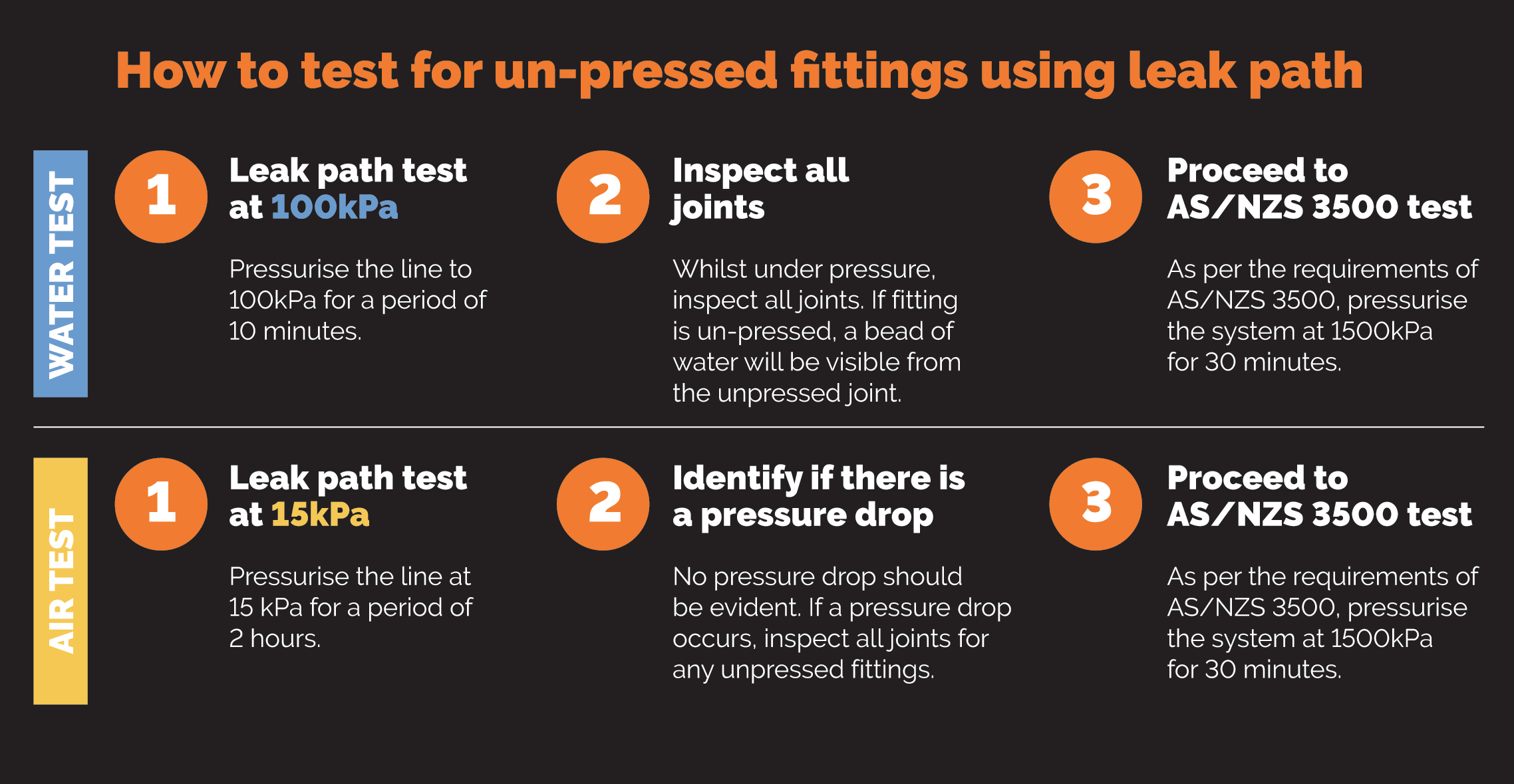

Unpressed Fitting ID – Leak Path

| KemPress Stainless fittings for Water and Gas are designed to allow a small amount of water or air to escape from any fitting that is un-pressed. This feature ensures a system isn’t commissioned with unpressed fittings installed that under high pressure may cause a temporary seal and cause a future leak and reduce the risk of costly failures, rectification and damage to property. The leak path feature is activated by performing a low pressure test prior to normal pressure testing as below. |

Push & Stay Technology

Press copper fittings up to DN50 are equipped with the unique ‘Push & Stay’ feature. Utilising strict process control, the tightest of manufacturing tolerances and the most accurate production technology, KemPress fittings have been designed to ensure the fitting is tight enough to stay on the tube prior to pressing. Such a feature is symbolic of the high quality manufacturing and quality control processes employed during manufacture. KemPress “Push & Stay” has been designed to minimise risk during the installation process and make KemPress fittings easier to install with the following benefits:

|

Bluetooth Equipped KemPress Tools

| KemPress KPS2 and KPL3 press tools are equipped with smart Bluetooth technology so you can stay fully connected with your job site and installation performance. The innovative technology combined with the Novocheck App means you can manage the job straight from your smart phone or tablet. The ability to monitor and maintain your tool performance as well as installation performance reduces installation risk and increases the quality of your installations. Pre-start tool checks will ensure your tools are ready to work, service logs will mean you can see when your tool needs its next service and generation of site reports means you can detect any unpressed fittings by comparing the number of completed presses to those required on each section of work.

Download the NovoCheck App from the App Store or Google Play and connect with your tool today. |

KemPress Stainless Fittings are available in 3 types based on their application and O-ring; Water, Gas & High Temperature. Inside each fitting is a sealing element called an Elastomeric O-ring. Fittings are available for Water (EPDM – Black), Gas (HNBR – Yellow) and High Temperature/Industry (FKM – Red). They are not interchangeable for their different applications.

KemPress Stainless fittings are manufactured and quality controlled to AS3688, with 316L (material EN1.4404) for parts made from tube, 316Ti (material EN1.4571) for threaded fittings and 316 (material 1.4408) for precision cast fittings, all having Watermark Approval # 23087 for Standard (EPDM) and Industry (FKM) fittings.

KemPress fittings are not suitable for Medical Gas, Refrigeration & Air Conditioning applications, Acetylene, Urea Solution, Methanol, Glycerin Triacetate, Coolant Inhibitor, Sodium Hydroxide or Ammoniac-gaseous.

For further information regarding suitability of KemPress fittings for applications, refer to the Application Guide downloadable in the “Support” section at the bottom of this page contact MM Kembla customer service.

Water

|

Standard press fittings utilise a black EPDM (Ethylene Propylene Diene Monomer) O-ring sealing element. This O-ring is suitable for hot and cold potable water applications and some industrial applications. It is not suitable for aromatic hydrocarbons, di-ester based lubricants, halogenated solvents or petroleum based oils and greases. |

Gas

|

Gas applications use a HNBR (Hydrogenated Nitrile Butadiene Rubber) O-ring sealing element. HNBR has been used for decades in automotive and industrial applications. It is designed for gas, oil and chemical resistance. It is not suitable for drinking water. Gas fittings have a yellow O-ring and are clearly marked with a distinctive yellow colour and the word GAS. |

High Temperature (HT)

|

Industry or High temperature applications use an FKM (fluorocarbon) O-ring sealing element. Ideal for petroleum products, fuels including those blended with ethanol or methanol, diesel, biodiesel, mineral oils and greases, silicone oils and greases, high vacuum, strong acids, ozone, weather and very high temperatures. This O-ring is suitable for applications where temperatures exceed 120°C (up to 200°C), often at the collector. HT fittings have a red O-ring and are clearly marked with a distinctive red colour and the word HT. |

KemPress Stainless O-Ring Specifications

| Colour Code | Black | Red | Yellow |

| Fitting Type | Standard | Industry | Gas |

| Material Code | EPDM | FKM | HNBR |

| Material | Ethylene Propylene Diene Monomer | Fluorocarbon | Hydrogenated Nitrile Butadiene Rubber |

| Maximum Continuous Temperature Range °C | -30°C up to 120°C | -20°C up to 200°C (depending on the medium) | -20°C up to 100°C |

| Peak Short Term Max. Temp °C | 150°C | 280°C | 100°C |

KemPress Stainless Design Pressures Using Standard Tools, Jaws and Slings

| Application | Pipe External Diameter | Safe Working Pressure |

|---|---|---|

| Water and Aqueous Solutions | d ≤ 22mm | 40 bar |

| d = 28-35mm | 25 bar | |

| d = 42-108mm | 16 bar | |

| Flammable/Fuel Gases | d ≤ 108mm | 5 bar |

| Technical Gases & Compressed Air (Non-Toxic, Non-Flammable) | d ≤ 108mm | 16 bar |

| Fire Sprinkler Systems | d = 22-76.1mm | 16 bar (EPDM & FKM for VdS) |

| 12 bar (EPDM & FKM for FM) | ||

| d = 108 mm | 12.5 bar (EPDM only for VdS) | |

| 12 bar (EPDM & FKM for FM) |

MM Kembla guarantees the leak tightness of the KemPress Stainless pressed joints for standard potable water and gas applications, regardless of the manufacturer of the pressing tools, providing the pressing machines and pressing jaws and/ or slings meet the following requirements:

- The pressing tools must be maintained and used according to the respective manufacturer’s guidelines.

- KemPress press tools and standard pressure jaws/slings are fully compliant as follows:

- KPS/KPS2 or tools with min. press force of 18kN for 15 mm – 28 mm inclusive

- KPL/KPL2/KPL3 or tools with min. press force of 30kN for 15 mm – 54 mm inclusive

- KPXL/KPXL2 or tools with min. press force of 32kN for 15 mm – 108 mm inclusive

- The correct EN size jaw/sling shall be used for the fitting

- With KemPress Stainless fittings up to including 54 mm in diameter, pressing jaws and slings for press connections of the type M-MM must exhibit the original profiles SA, M or V

- With KemPress Stainless fittings greater than 54 mm in diameter, pressing jaws and slings for press connections of the type M-MM must exhibit the original profiles M.

- Fast & easy to use – Considerably faster than traditional jointing methods

- No need to drain water out of the system

- No waiting for adhesives to set

- Flame free connection – no hot works permit required and ideal for retrofit projects

- Same tools used for the KemPress® Copper system, simply change jaws, adaptors and slings to suit stainless and press profile as required.

- High quality fittings manufactured and quality controlled to AS 3688

- High quality 316L stainless steel ensures higher corrosion resistance

- Push & Stay feature

- Unpressed Fitting ID (Leak Path) feature

- Watermark Certified (Fittings Licence no. 23087, Tube Licence no. 23151)

- FM and VdS approved for sizes 22-108mm with EPDM for wet systems and FKM O-ring for wet and dry systems

- 25 Year Warranty for potable water and fuel gas applications

- 10 Year Warranty for industrial applications subject to MM Kembla written confirmation of product suitability.

10 Years (Industrial Applications)For industrial applications, subject to MM Kembla confirming in writing that the products are suitable for the application, MM Kembla guarantees that the tube and fittings will be fit for their intended purpose for a period of not less than 10 years. MM Kembla warrants that if any installation using KemPress fittings becomes defective or fails and MM Kembla is notified of the details and is satisfied that the defect or failure was a result of a manufacturing defect and not the result of faulty specification, installation or incompatible environment, MM Kembla will replace or repair the defective goods and make good the installation. |

|

25 Years (Potable Water and Fuel Gas Applications)An intensive ISO 9001 certified quality control system is applied to all MM Kembla KemPress fittings to ensure they confirm to AS3688 and Australian Watermark certification requirements. MM Kembla warrants that if any installation using KemPress fittings becomes defective or fails and MM Kembla is notified of the details and is satisfied that the defect or failure was a result of a manufacturing defect and not the result of faulty specification, installation or incompatible environment, MM Kembla will replace or repair the defective goods and make good the installation. |

|

KEMPRESS STAINLESS FITTINGS – PRODUCT TABLES

| Diameter | Code | Pack Qty |

|---|---|---|

| 15 | X95250 | 100 |

| 22 | X95251 | 70 |

| 28 | X95252 | 40 |

| 35 | X95253 | 30 |

| 42 | X95254 | 20 |

| 54 | X95255 | 10 |

| 76.1 | X95256 | 5 |

| 108 | X95257 | 5 |

| Diameter | Water Code | Pack Qty | Gas Code | Pack Qty | Industry Code | Pack Qty |

|---|---|---|---|---|---|---|

| 15 | X95300 | MTO | X95320 | 10 | X95310 | 10 |

| 22 | X95301 | MTO | X95321 | 10 | X95311 | 10 |

| 28 | X95302 | MTO | X95322 | 5 | X95312 | 5 |

| 35 | X95303 | MTO | X95323 | 2 | X95313 | 2 |

| 42 | X95304 | MTO | X95324 | 2 | X95314 | 2 |

| 54 | X95305 | MTO | X95325 | 2 | X95315 | 2 |

| 76.1 | X95306 | MTO | X95326 | 1 | X95316 | 1 |

| 108 | X95307 | MTO | X95327 | 1 | X95317 | 1 |

| Diameter | Water Code | Pack Qty | Gas Code | Pack Qty | Industry Code | Pack Qty |

|---|---|---|---|---|---|---|

| 15 | X95350 | MTO | X95370 | 10 | X95360 | 10 |

| 22 | X95351 | MTO | X95371 | 10 | X95361 | 10 |

| 28 | X95352 | MTO | X95372 | 5 | X95362 | 5 |

| 35 | X95353 | MTO | X95373 | 2 | X95363 | 2 |

| 42 | X95354 | MTO | X95374 | 2 | X95364 | 2 |

| 54 | X95355 | MTO | X95375 | 2 | X95365 | 2 |

| 76.1 | X95356 | MTO | X95376 | 1 | X95366 | 1 |

| 108 | X95357 | MTO | X95377 | 1 | X95367 | 1 |

| Diameter | Water Code | Pack Qty | Gas Code | Pack Qty | Industry Code | Pack Qty |

|---|---|---|---|---|---|---|

| 15 | X95500 | 10 | X95520 | 10 | X95510 | 10 |

| 22 | X95501 | 10 | X95521 | 10 | X95511 | 10 |

| 28 | X95502 | 5 | X95522 | 5 | X95512 | 5 |

| 35 | X95503 | 2 | X95523 | 2 | X95513 | 2 |

| 42 | X95504 | 2 | X95524 | 2 | X95514 | 2 |

| 54 | X95505 | 2 | X95525 | 2 | X95515 | 2 |

| 76.1 | X95506 | 1 | X95526 | 1 | X95516 | 1 |

| 108 | X95507 | 1 | X95527 | 1 | X95517 | 1 |

| Diameter | Water Code | Pack Qty | Gas Code | Pack Qty | Industry Code | Pack Qty |

|---|---|---|---|---|---|---|

| 15 | X95450 | 10 | X95470 | 10 | X95460 | 10 |

| 22 | X95451 | 10 | X95471 | 10 | X95461 | 10 |

| 28 | X95452 | 5 | X95472 | 5 | X95462 | 5 |

| 35 | X95453 | 2 | X95473 | 2 | X95463 | 2 |

| 42 | X95454 | 2 | X95474 | 2 | X95464 | 2 |

| 54 | X95455 | 2 | X95475 | 2 | X95465 | 2 |

| 76.1 | X95456 | 1 | X95476 | 1 | X95466 | 1 |

| 108 | X95457 | 1 | X95477 | 1 | X95467 | 1 |

| Diameter | Water Code | Pack Qty | Gas Code | Pack Qty | Industry Code | Pack Qty |

|---|---|---|---|---|---|---|

| 15 x 1/2 | X95600 | MTO | X95620 | 10 | X95610 | 10 |

| 22 x 3/4 | X95601 | MTO | X95621 | 10 | X95611 | 10 |

| 28 x 1 | X95602 | MTO | X95622 | 5 | X95612 | 5 |

| 35 x 1 1/4 | X95603 | MTO | X95623 | 2 | X95613 | 2 |

| 42 x 1 1/2 | X95604 | MTO | X95624 | 2 | X95614 | 2 |

| 54 x 2 | X95605 | MTO | X95625 | 2 | X95615 | 2 |

| Diameter | Water Code | Pack Qty | Gas Code | Pack Qty | Industry Code | Pack Qty |

|---|---|---|---|---|---|---|

| 15 x 1/2 | X95550 | MTO | X95570 | 10 | X95560 | 10 |

| 22 x 3/4 | X95551 | MTO | X95571 | 10 | X95561 | 10 |

| 28 x 1 | X95552 | MTO | X95572 | 5 | X95562 | 5 |

| 35 x 1 1/4 | X95553 | MTO | X95573 | 2 | X95563 | 2 |

| Diameter | Water Code | Pack Qty | Gas Code | Pack Qty | Industry Code | Pack Qty |

|---|---|---|---|---|---|---|

| 15 | X95700 | MTO | X95720 | 10 | X95710 | 10 |

| 22 | X95701 | MTO | X95721 | 10 | X95711 | 10 |

| 28 | X95702 | MTO | X95722 | 5 | X95712 | 5 |

| 35 | X95703 | MTO | X95723 | 2 | X95713 | 2 |

| 42 | X95704 | MTO | X95724 | 2 | X95714 | 2 |

| 54 | X95705 | MTO | X95725 | 2 | X95715 | 2 |

| 76.1 | X95706 | MTO | X95726 | 1 | X95716 | 1 |

| 108 | X95707 | MTO | X95727 | 1 | X95717 | 1 |

| Diameter | Water Code | Pack Qty | Gas Code | Pack Qty | Industry Code | Pack Qty |

|---|---|---|---|---|---|---|

| 15 | X95650 | MTO | X95670 | 10 | X95660 | 10 |

| 22 | X95651 | MTO | X95671 | 10 | X95661 | 10 |

| 28 | X95652 | MTO | X95672 | 5 | X95662 | 5 |

| 35 | X95653 | MTO | X95673 | 2 | X95663 | 2 |

| 42 | X95654 | MTO | X95674 | 2 | X95664 | 2 |

| 54 | X95655 | MTO | X95675 | 2 | X95665 | 2 |

| 76.1 | X95656 | MTO | X95676 | 1 | X95666 | 1 |

| 108 | X95657 | MTO | X95677 | 1 | X95667 | 1 |

| Diameter | Water Code | Pack Qty | Gas Code | Pack Qty | Industry Code | Pack Qty |

|---|---|---|---|---|---|---|

| 22 x 15 | X95400 | MTO | X95428 | 10 | X95414 | 10 |

| 28 x 15 | X95401 | MTO | X95429 | 5 | X95415 | 5 |

| 28 x 22 | X95402 | MTO | X95430 | 5 | X95416 | 5 |

| 35 x 22 | X95403 | MTO | X95431 | 2 | X95417 | 2 |

| 35 x 28 | X95404 | MTO | X95432 | 2 | X95418 | 2 |

| 42 x 22 | X95405 | MTO | X95433 | 2 | X95419 | 2 |

| 42 x 28 | X95406 | MTO | X95434 | 2 | X95420 | 2 |

| 42 x 35 | X95407 | MTO | X95435 | 2 | X95421 | 2 |

| 54 x 28 | X95408 | MTO | X95436 | 2 | X95422 | 2 |

| 54 x 35 | X95409 | MTO | X95437 | 2 | X95423 | 2 |

| 54 x 42 | X95410 | MTO | X95438 | 2 | X95424 | 2 |

| 76 x 54 | X95411 | MTO | X95439 | 2 | X95425 | 2 |

| 108 x 54 | X95412 | MTO | X95440 | 2 | X95426 | 2 |

| 108 x 76 | X95413 | MTO | X95441 | 2 | X95427 | 2 |

| Diameter | Water Code | Pack Qty | Gas Code | Pack Qty | Industry Code | Pack Qty |

|---|---|---|---|---|---|---|

| 15 | X96850 | MTO | X96870 | 10 | X96860 | 10 |

| 22 | X96851 | MTO | X96871 | 10 | X96861 | 10 |

| 28 | X96852 | MTO | X96872 | 5 | X96862 | 5 |

| 35 | X96853 | MTO | X96873 | 2 | X96863 | 2 |

| 42 | X96854 | MTO | X96874 | 2 | X96864 | 2 |

| 54 | X96855 | MTO | X96875 | 2 | X96865 | 2 |

| Diameter | Water Code | Pack Qty | Gas Code | Pack Qty | Industry Code | Pack Qty |

|---|---|---|---|---|---|---|

| 15 | X96250 | MTO | X96270 | 10 | X96260 | 10 |

| 22 | X96251 | MTO | X96271 | 10 | X96261 | 10 |

| 28 | X96252 | MTO | X96272 | 5 | X96262 | 5 |

| 35 | X96253 | MTO | X96273 | 2 | X96263 | 2 |

| 42 | X96254 | MTO | X96274 | 2 | X96264 | 2 |

| 54 | X96255 | MTO | X96275 | 2 | X96265 | 2 |

| 76.1 | X96256 | MTO | X96276 | 1 | X96266 | 1 |

| 108 | X96257 | MTO | X96277 | 1 | X96267 | 1 |

| Diameter | Water Code | Pack Qty | Gas Code | Pack Qty | Industry Code | Pack Qty |

|---|---|---|---|---|---|---|

| 22 x 15 x 22 | X96300 | MTO | X96400 | 10 | X96350 | 10 |

| 28 x 15 x 28 | X96301 | MTO | X96401 | 5 | X96351 | 5 |

| 28 x 22 x 28 | X96302 | MTO | X96402 | 5 | X96352 | 5 |

| 35 x 22 x 35 | X96304 | MTO | X96404 | 2 | X96354 | 2 |

| 35 x 28 x 35 | X96305 | MTO | X96405 | 2 | X96355 | 2 |

| 42 x 22 x 42 | X96306 | MTO | X96406 | 2 | X96356 | 2 |

| 42 x 28 x 42 | X96307 | MTO | X96407 | 2 | X96357 | 2 |

| 42 x 35 x 42 | X96308 | MTO | X96408 | 2 | X96358 | 2 |

| 54 x 22 x 54 | X96309 | MTO | X96409 | 2 | X96359 | 2 |

| 54 x 28 x 54 | X96310 | MTO | X96410 | 2 | X96360 | 2 |

| 53 x 35 x 54 | X96311 | MTO | X96411 | 2 | X96361 | 2 |

| 54 x 42 x 54 | X96312 | MTO | X96412 | 2 | X96362 | 2 |

| 76 x 28 x 76 | X96314 | MTO | X96414 | 1 | X96364 | 1 |

| 76 x 54 x 76 | X96317 | MTO | X96417 | 1 | X96367 | 1 |

| 108 x 54 x 108 | X96322 | MTO | X96422 | 1 | X96372 | 1 |

| 108 x 76 x 108 | X96323 | MTO | X96423 | 1 | X96373 | 1 |

| Diameter | Water Code | Pack Qty | Gas Code | Pack Qty | Industry Code | Pack Qty |

|---|---|---|---|---|---|---|

| 15 x 1/2 | X96450 | MTO | X96550 | 10 | X96500 | 10 |

| 22 x 1/2 | X96451 | MTO | X96551 | 5 | X96501 | 5 |

| 22 x 3/4 | X96452 | MTO | X96552 | 10 | X96502 | 10 |

| 28 x 1/2 | X96453 | MTO | X96553 | 5 | X96503 | 5 |

| 35 x 1/2 | X96456 | MTO | X96556 | 2 | X96506 | 2 |

| 35 x 3/4 | X96457 | MTO | X96557 | 2 | X96507 | 2 |

| 42 x 1/2 | X96459 | MTO | X96559 | 2 | X96509 | 2 |

| 42 x 3/4 | X96460 | MTO | X96560 | 2 | X96510 | 2 |

| 54 x 1/2 | X96462 | MTO | X96562 | 2 | X96512 | 2 |

| 54 x 3/4 | X96463 | MTO | X96563 | 2 | X96513 | 2 |

| 54 x 2 | X96464 | MTO | X96564 | 2 | X96514 | 2 |

| 76.1 x 3/4 | X96465 | MTO | X96565 | 1 | X96515 | 1 |

| 76.1 x 2 | X96466 | MTO | X96566 | 1 | X96516 | 1 |

| 108 x 3/4 | X96467 | MTO | X96567 | 1 | X96517 | 1 |

| 108 x 2 | X96468 | MTO | X96568 | 1 | X96518 | 1 |

| Diameter | Water Code | Pack Qty |

|---|---|---|

| 22 | X97001 | MTO |

| 28 | X97002 | MTO |

| 35 | X97003 | MTO |

| 42 | X97004 | MTO |

| 54 | X97005 | MTO |

| 76.1 | X97006 | MTO |

| 108 | X97007 | MTO |

| Diameter | Water Code | Pack Qty | Gas Code | Pack Qty | Industry Code | Pack Qty |

|---|---|---|---|---|---|---|

| 15 x 1/2 | X96050 | MTO | X96076 | 10 | X96063 | 10 |

| 15 x 3/4 | X96051 | MTO | X96077 | 10 | X96064 | 10 |

| 22 x 1/2 | X96052 | MTO | X96078 | 10 | X96065 | 10 |

| 22 x 3/4 | X96053 | MTO | X96079 | 10 | X96066 | 10 |

| 22 x 1 | X96054 | MTO | X96080 | 10 | X96067 | 10 |

| 28 x 3/4 | X96055 | MTO | X96081 | 5 | X96068 | 5 |

| 28 x 1 | X96056 | MTO | X96082 | 5 | X96069 | 5 |

| 35 x 1 1/4 | X96058 | MTO | X96084 | 2 | X96071 | 2 |

| 42 x 1 1/2 | X96059 | MTO | X96085 | 2 | X96072 | 2 |

| 54 x 2 | X96060 | MTO | X96086 | 2 | X96073 | 2 |

| 76.1 x 2 1/2 | X96061 | MTO | X96087 | 1 | X96074 | 1 |

| 108 x 4 | X96062 | MTO | X96088 | 1 | X96075 | 1 |

| Diameter | Water Code | Pack Qty | Gas Code | Pack Qty | Industry Code | Pack Qty |

|---|---|---|---|---|---|---|

| 15 x 1/2 | X96150 | MTO | X96170 | 10 | X96160 | 10 |

| 15 x 3/4 | X96151 | MTO | X96171 | 10 | X96161 | 10 |

| 22 x 1/2 | X96152 | MTO | X96172 | 10 | X96162 | 10 |

| 22 x 3/4 | X96153 | MTO | X96173 | 10 | X96163 | 10 |

| 28 x 3/4 | X96155 | MTO | X96175 | 5 | X96165 | 5 |

| 28 x 1 | X96156 | MTO | X96176 | 5 | X96166 | 5 |

| 35 x 1 1/4 | X96157 | MTO | X96177 | 2 | X96167 | 2 |

| 42 x 1 1/2 | X96158 | MTO | X96178 | 2 | X96168 | 2 |

| 54 x 2 | X96159 | MTO | X96179 | 2 | X96169 | 2 |

| Diameter | Water Code | Pack Qty | Gas Code | Pack Qty | Industry Code | Pack Qty |

|---|---|---|---|---|---|---|

| 15 x 1/2 | X96700 | MTO | X96720 | 5 | X96710 | 5 |

| 15 x 3/4 | X96701 | MTO | X96721 | 5 | X96711 | 5 |

| 22 x 3/4 | X96702 | MTO | X96722 | 5 | X96712 | 5 |

| 28 x 1 | X96705 | MTO | X96725 | 5 | X96715 | 5 |

| 35 x 1 1/4 | X96706 | MTO | X96726 | 2 | X96716 | 2 |

| 42 x 1 1/2 | X96707 | MTO | X96727 | 2 | X96717 | 2 |

| 54 x 2 | X96708 | MTO | X96728 | 2 | X96718 | 2 |

| Diameter | Water Code | Pack Qty | Gas Code | Pack Qty | Industry Code | Pack Qty |

|---|---|---|---|---|---|---|

| 15 x 1/2 | X96750 | MTO | X96770 | 5 | X96760 | 5 |

| 15 x 3/4 | X96751 | MTO | X96771 | 5 | X96761 | 5 |

| 22 x 3/4 | X96752 | MTO | X96772 | 5 | X96762 | 5 |

| 28 X 1 | X96753 | MTO | X96773 | 5 | X96763 | 5 |

| 35 x 1 1/4 | X96754 | MTO | X96774 | 2 | X96764 | 2 |

| 42 x 1 1/2 | X96755 | MTO | X96775 | 2 | X96765 | 2 |

| 54 x 2 | X96756 | MTO | X96776 | 2 | X96766 | 2 |

| Diameter | Water Code | Pack Qty | Gas Code | Pack Qty | Industry Code | Pack Qty |

|---|---|---|---|---|---|---|

| 15 x 1/2 | X96600 | MTO | X96620 | 10 | X96610 | 10 |

| 15 x 3/4 | X96601 | MTO | X96621 | 10 | X96611 | 10 |

| Diameter | Water Code | Pack Qty | Gas Code | Pack Qty | Industry Code | Pack Qty |

|---|---|---|---|---|---|---|

| 15 | X97760 | 1 | X97750 | 1 | X97740 | 1 |

| 22 | X97761 | 1 | X97751 | 1 | X97741 | 1 |

| 28 | X97762 | 1 | X97752 | 1 | X97742 | 1 |

| 35 | X97763 | 1 | X97753 | 1 | X97743 | 1 |

| 42 | X97764 | 1 | X97754 | 1 | X97744 | 1 |

| 54 | X97765 | 1 | X97755 | 1 | X97745 | 1 |

| 76 | X97766 | 1 | X97756 | 1 | X97746 | 1 |

| 108 | X97767 | 1 | X97757 | 1 | X97747 | 1 |

| Diameter | Water Code | Pack Qty | Gas Code | Pack Qty | Industry Code | Pack Qty |

|---|---|---|---|---|---|---|

| 15 | X97760 | 1 | X97750 | 1 | X97740 | 1 |

| 22 | X97761 | 1 | X97751 | 1 | X97741 | 1 |

| 28 | X97762 | 1 | X97752 | 1 | X97742 | 1 |

| 35 | X97763 | 1 | X97753 | 1 | X97743 | 1 |

| 42 | X97764 | 1 | X97754 | 1 | X97744 | 1 |

| 54 | X97765 | 1 | X97755 | 1 | X97745 | 1 |

| 76 | X97766 | 1 | X97756 | 1 | X97746 | 1 |

| 108 | X97767 | 1 | X97757 | 1 | X97747 | 1 |

| Diameter | Water Code | Pack Qty | Gas Code | Pack Qty | Industry Code | Pack Qty |

|---|---|---|---|---|---|---|

| 18mm for 22 x 3/4 | X96650 | 1 | Universal | Universal | Universal | Universal |

| 25mm for 15 x 1/2 | X96651 | 1 | Universal | Universal | Universal | Universal |

SUPPORT: DOWNLOAD FILES

KemPress Brochures & Materials